Improper cooling of food can allow bacteria to grow and cause food illness. Food must pass through the temperature danger zone quickly to reduce the growth of pathogens.

Cold or hot holding of food is a critical control point – or a point at which maintaining proper temperatures will help ensure food is safe to eat. Food handlers must know the proper temperature for holding food, monitor the holding process, and record temperatures of foods during holding.

TCS (Time/Temperature Control for Safety) food is a high risk food that requires specific time and temperature controls to remain safe for consumption. When cooling this type of food, the temperature must be reduced from 135°F to 41°F (57°C – 5°C) or lower – within 6 hours.

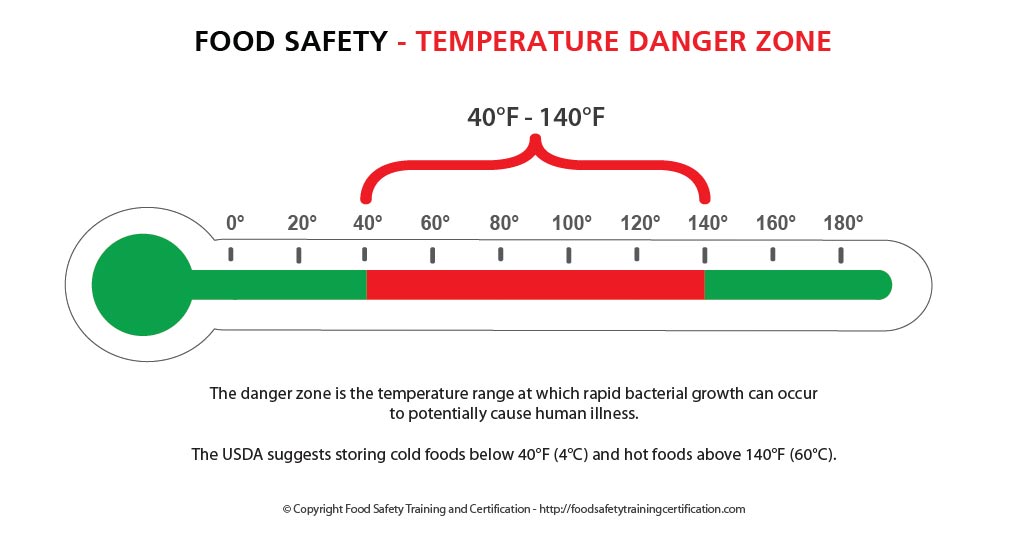

Bacteria Danger Zone

One of the leading causes of foodborne illness is the failure to properly cool foods. When cooking food that is not served immediately, it is important to get the food out of the bacteria temperature danger zone quickly.

- Learn about foodborne pathogens, cross contamination, cold and hot food safety, and best practices to prevent foodborne illness.

- Food Manager ANSI Certification: $99.00 - Valid in all States

- Food Handler Training: Only $7.00!

- 10% OFF: Enter Promo Code "train10off" at Checkout

The bacteria danger zone is the temperature between 40°F -140°F where pathogens grow most quickly.

Factors that Affect Cooling Food

- Type of food containers– Plastic containers hold on to heat – stainless steel or copper containers – draw heat away from food.

- Food thickness– The thicker or more dense the food, the slower it is to cool.

- Food size– Larger items cool slower than smaller items.

- Stirring– Stirring hot liquid foods helps them to cool faster. Ice paddles will expedite this process.

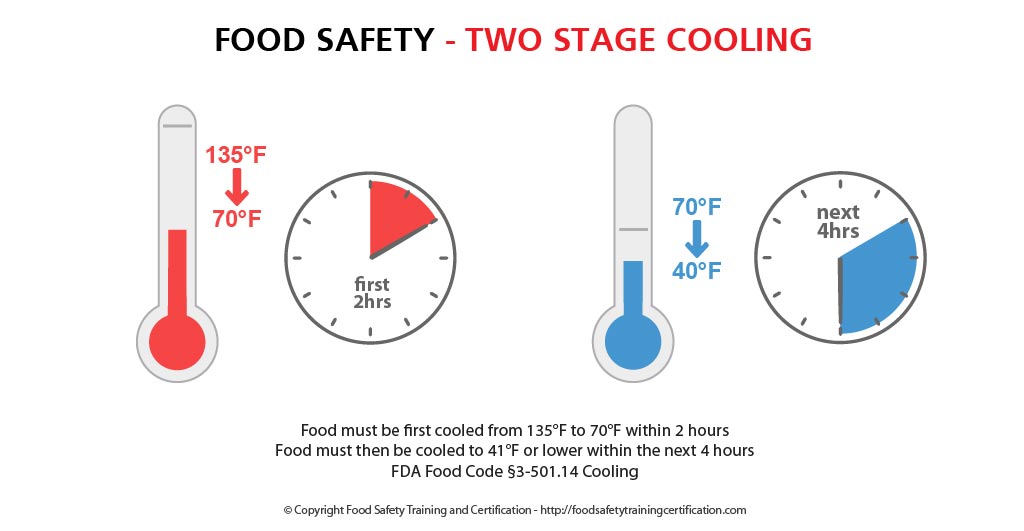

Two-Stage Safe Food Cooling

According to FDA Food Code §3-501.14 Cooling, the time/temperature control for the safety of food:

- Food must be cooled from 135°F to 70°F within 2 hours, then

- Food must be cooled to 41°F or lower within the next 4 hours – for a maximum cooling time of 6 hours.

Note: Initial 2-hour Cool is Critical – The initial 2-hour cool is the most critical time period since the food is passing through the temperature range that supports the most rapid microorganism growth. If food has not reached 70°F within 2 hours, it must be reheated and then cooled again – or thrown away.

Source: U.S. Food & Drug Administration (FDA). 2017 Food Code §3-501.14. Retrieved July 12, 2019, from https://www.fda.gov/food/fda-food-code/food-code-2017

Safe Rapid Cooling of Food

When prepping a large batch of hot food, plan ahead for the cooling method you plan to use. Begin your plan by having an accurate food thermometer to keep tabs on the temperature during the cooling process.

Start by reducing the size or mass of food by reducing larger food items into smaller portions and into smaller containers. Then, use the following methods and procedures to safely cool your hot food:

1.Use ice water bath – An ice water bath is effective for cooling. This method helps decrease the food temperature quickly and safely.

- Fill a large container or clean sink with ice and a small amount of water.

- Place the kettle of hot food into the ice bath.

- Stir the food to release heat and aid cooling.

2. Use shallow pans – The smaller the portions, the quicker the cool down.

- Don’t leave a large pot of hot food on the counter to cool before placing in the fridge.

- Separate into smaller containers, no deeper than 3 inches.

- Stir occasionally to aid cooling.

3. Use ice in the recipe – You can reduce cooling time by adapting your food recipe.

- Prepare a thicker amount of food, reducing the original amount of water or liquid called for in the recipe. Add ice to the food at the final preparation step.

4. Use cooling paddles – These are more commonly used in a commercial kitchen.

- The cooling paddle is filled with water and placed in the freezer.

- Stir the hot food, in the kettle with the frozen chill paddle.

- Shop for Cooling Paddles on Amazon

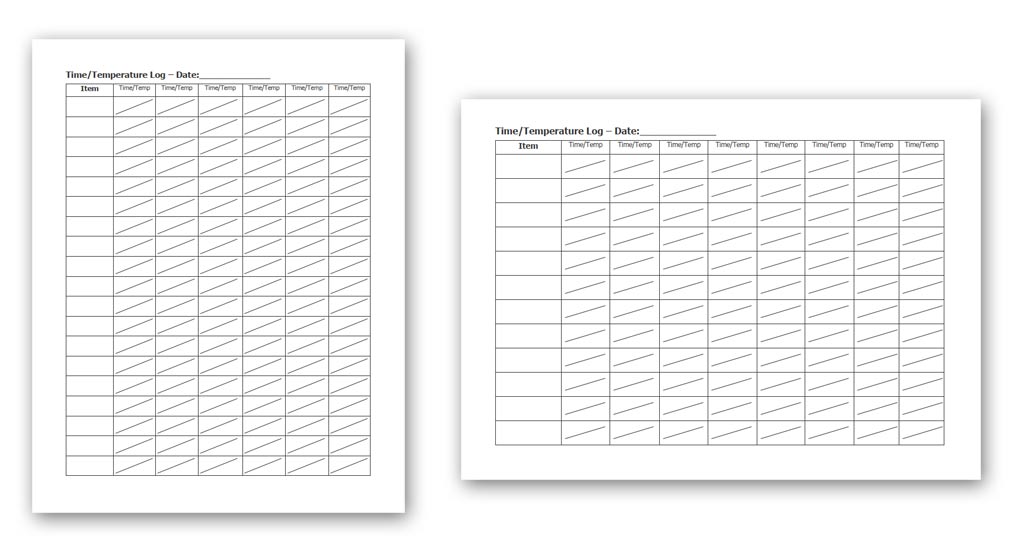

Record Keeping: Holding Times and Temperature Log

Because cooling food is generally an out of sight, out of mind process, using a time/temperature log will help to keep employees and yourself aware that food is in the cooling process.

Log forms are a useful tool and can be utilized for cooling foods as well as other food items (hot holding, cold holding, storage) and refrigerators.

The temperature log charts below offer food service workers a simple way to monitor and record temperatures.